Contact Us at

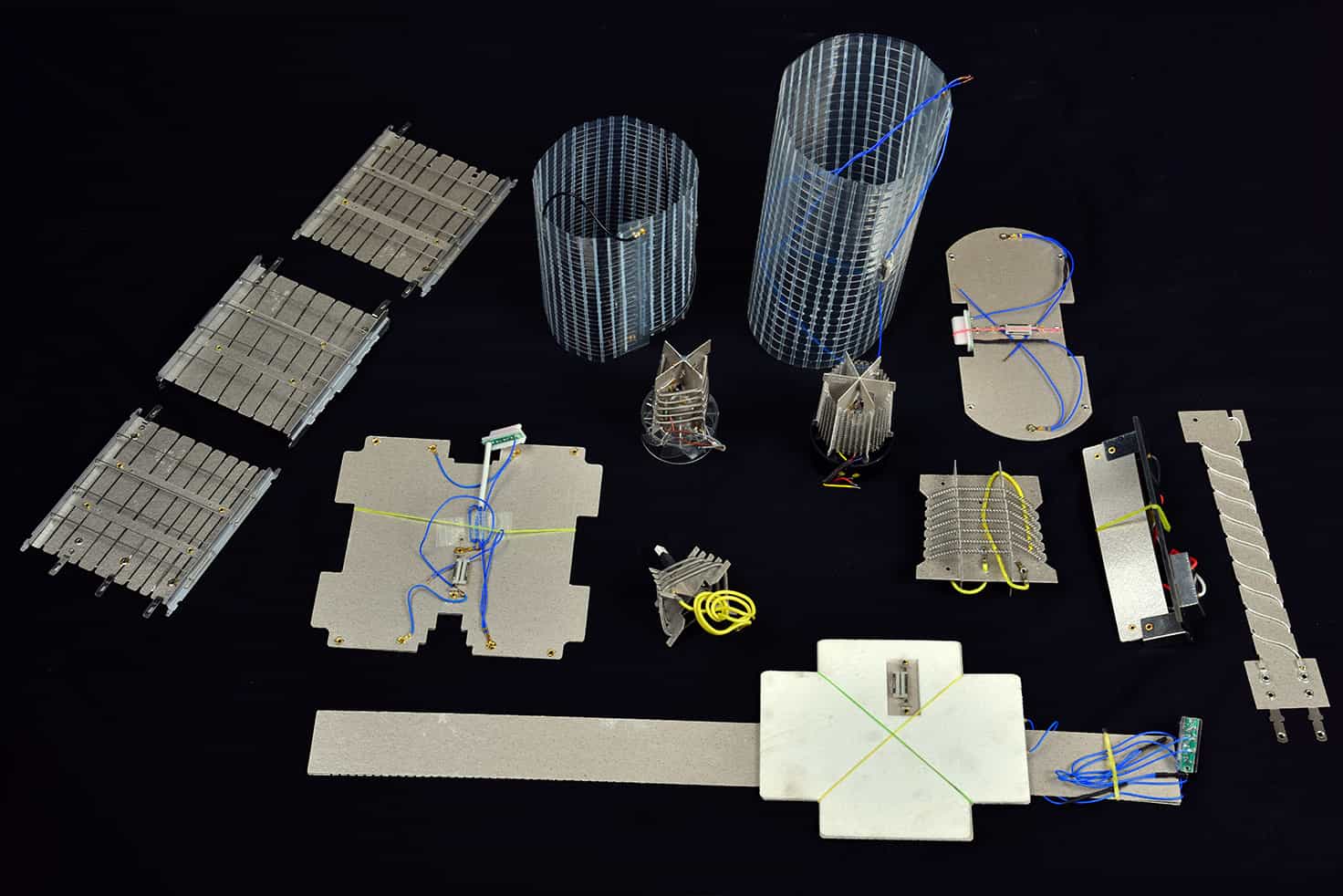

Electrical Heating Element Manufacturer in India

Description

India has witnessed significant industrial growth, and at the heart of many industries are Electrical Heating Element Manufacturer in India, Chhaperia Electro. These crucial components are responsible for generating heat in various applications, from industrial processes to household appliances. Chhaperia's product range includes a diverse selection of heating elements designed for various applications, from industrial processes to household appliances. With a strong focus on safety and adherence to international quality standards, Chhaperia has earned a reputation as a trusted and forward-thinking manufacturer in the field of electrical heating elements in India.

Product Info

Electrical heating elements are at the core of numerous heating applications, and Chhaperia is leading the charge in providing top-notch solutions. Mica-insulated resistance wire heating elements are essential for various heating applications, offering efficient and reliable heating solutions. We are leading the way in producing high-quality elements that combine resistance wire technology with advanced materials. Key features include a wound resistance wire in front of a mica insulating support, a thin mica cover for safety and durability, a chrome-coated steel stiffener for stability and heat reflection, and a reflector for optimal heat reflection and efficient heating. These elements are designed to maintain the element's shape and integrity during operation.

Documentation

Indian electrical heating element manufacturers are committed to quality and safety. To support this commitment, they provide comprehensive documentation, including Quality and safety are at the core of Chhaperia Electro Components's values. To substantiate this commitment, we have obtained several certifications and documentation. Notably, our mica heaters have earned TUV Certification, attesting to their safety and reliability. We are also proud to announce our Reach compliance, ensuring that our mica heaters are devoid of any substances that could potentially harm human health or the environment. Moreover, our stringent adherence to the ROHS directive guarantees that our mica heaters are completely free from hazardous materials. Our ISO 9001:2015 certification serves as a clear affirmation of our dedication to maintaining the highest standards of quality in both our products and manufacturing processes.

Applications

Electrical heating elements from Indian manufacturers find applications across a spectrum of industries, including

Industrial Processes: Used in heating tanks, boilers, ovens, and furnaces in industries such as manufacturing, chemicals, and textiles.

Household Appliances: Found in water heaters, room heaters, and kitchen appliances like ovens and toasters

Healthcare: Utilized in medical devices for diagnostics, sterilization, and patient care.

Food Industry: Essential for cooking, baking, and food processing equipment.

Automotive: Used in applications like plastic molding, adhesive curing, and engine preheating.

Aerospace: Critical for aircraft de-icing and cabin heating.

Electrical Heating Element Manufacturers in India play a pivotal role in powering various industries with efficient and reliable heating solutions. Their commitment to quality and safety, backed by rigorous documentation and certifications, makes them trusted partners for heating needs across a broad range of applications.

Similar links: electric-tiffin

Reference links: cassorol