Contact Us at

Mica Heater Manufacturer

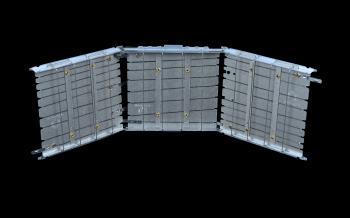

Description

Chhaperia Electro Components is a market-leading mica heater manufacturer, specialising in a wide range of electrical heating elements. Found in the year 1994, we have grown steadily over the years to become the most preferred choice for quality-driven heating elements for different types of requirements. Our units support multiple sectors including food & beverage along with plastic manufacturing and healthcare and aerospace and many other sectors which drive the regional industrial growth. Our business provides a wide range of heating elements for toasters along with electric kettles, ovens, hand dryers, room heaters and incubators.

Product Info

The heaters utilise high-precision resistance wire surrounding mica insulation to produce even heat distribution along with dependable operational outcomes. The added aluminised steel side bracket makes the heating element both durable and structurally robust. Users can choose between lead terminal materials for this product which supports different types of electrical connections. The heaters benefit from durability through a bread guard which consists of SS304 stainless steel material. The lead terminal material system exists among different heater variants.

Hand Dryer Mica Heater: Designed for rapid, efficient, and safe drying experiences, these heaters ensure quick drying and energy efficiency.

Snack Maker Mica Heater: Guarantee consistent and even heating for preparing snacks easily and precisely.

Hair Dryer Mica Heater: Provide controlled, gentle heat for salon-quality results and fast drying without damaging the hair.

Food Warmer Mica Heater: Maintain the perfect temperature to keep food warm and preserve its taste and quality.

Our primary focus as a top-tier mica heater manufacturer is to ensure that we provide our esteemed customers with an extensive selection of heating devices that will help them meet their organisational goals and also improve the quality of life for all. All you have to do is approach our team and put your requirements forward so we can identify the right heating solution for you.

Specification

Chhaperia Electro Components works tirelessly to ensure it adheres to all relevant quality and safety standards, ensuring our customers of our commitment and expertise as a premier mica heater manufacturer. Here are some of the details:

TUV Certification: Every mica heater we produce meets the stringent safety standards set by TUV.

Reach Compliance: Our Micra heaters are Reach compliance, ensuring it doesn’t contain any harmful substances.

ROHS Compliance: The company adheres to ROHS standards, meaning our mica heaters are free from any type of hazardous materials.

ISO 9001:2015 Certification: We comply with ISO 9001:2015 standards which serves as a testament to our commitment to maintaining the highest level of quality in all our offerings.

Mica Heater Manufacturer - Applications & Scope

A mica heater is a high-performance heating element designed for efficient and uniform heat distribution in industrial applications. They are constructed with a thin layer of mica insulation, offering excellent thermal conductivity, fast heating, and high dielectric strength. They are widely used in plastic processing, packaging, medical equipment, and other industries requiring precise temperature control. These heaters are durable, lightweight, and capable of withstanding high temperatures, making them a reliable choice for various heating applications.

Plastic Processing: Widely used in injection moulding machines, extruders, and blow moulding equipment. It ensures consistent heat to maintain optimal polymer flow.

Packaging Machinery: Provides fast and controlled heating for sealing bars, shrink tunnels, and hot stamping. This enhances production speed while maintaining seal integrity.

Food Processing: Used in food sealing machines while ensuring the food quality is maintained. These devices are compliant with food-grade safety standards.

Medical & Laboratory Equipment: Applied in sterilisation devices, incubators, and diagnostic instruments. Delivers precise, stable temperatures for sensitive processes.

Automotive & Aerospace: Provides lightweight, high-performance heating for battery pre-conditioning, de-icing systems, and composite curing.

Printing & Textile Industry: Maintains consistent heat in laminators, heat presses, and drying systems.

Considering the wide-ranging applications of this device, the demand for mica heater manufacturers is expected to continue on an upward trajectory for the foreseeable future.

Our mica heaters can be customised to meet various specifications, including voltage, temperature range, shape, size, and material used among other factors. This way, we can produce devices that meet your exact needs while complying with relevant industry standards.

What We Offer As A Leading Mica Heater Manufacturer

Low-Costing Products: Our heating elements are low-cost and yet provide the most reliable thermal solutions for a variety of needs. This is achieved by optimising material selection, production efficiency, and bulk manufacturing. This way, we continue to serve the needs of our valued partners while reducing their financial burden.

Custom Solutions: Every customer we serve has different needs depending on their application and the industry they are associated with. In light of this, we offer our partners a wide selection of standardised heating elements and also custom-built options. Whether you require a specific size, shape, temperature range, or material type, we leverage our expertise and modern technology to deliver exactly what you require.

Quality Compliance: This goes without saying – if we don’t serve the best product or service, we lose our customers eventually. For this reason, every aspect of our operations is underlined by strict adherence to various quality control measures. As mentioned earlier in the article, we comply with TUV, Reach, ROHS, and ISO 9001:2015 certifications. These accreditations not only guarantee quality-driven products but also instil the confidence our partners need while investing in our products.

Timely Delivery: This is yet another important factor that serves as the backbone of all our endeavours. Ensuring timely delivery means minimal delay and downtime in operations, leading to increased efficiency and profitability. With our clients located across the country, we have worked over time to develop a network of warehouses and distributors who ensure we continue to meet deadlines without compromising quality.

Customer Focus: At Chhaperia Electro Components, we don’t just direct our efforts at manufacturing high-quality heating elements – we also work on building partnerships. This means we work closely with our customers to understand their needs, and challenges, and then offer solutions that are designed around these aspects. Additionally, we also provide comprehensive after-sales support which includes troubleshooting, regular maintenance, warranty service, and spare part replacement. Such services will extend the lifespan of your device while also ensuring your operations are never hampered. Whatever your need, we stand behind every product we deliver and continue to deliver service excellence each time.

Choose the best mica heater manufacturer, and choose Chhaperia Electro Components!

Similar links: Mica Heating Element

Reference links: Mica Heaters